Extraction Tower Filler Technology Series Products

-

Pipeline reactor

-

Tower reactor

-

Tubular high efficiency heat exchanger

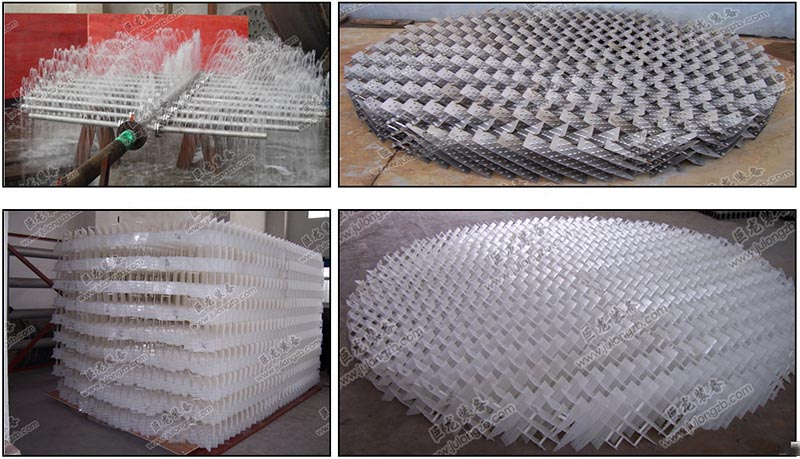

After years of collaborative research with the Department of Chemical Engineering at Tsinghua University, our company has developed a new technology for honeycomb (FG) series structured packing extraction towers, which has been successfully applied in liquid-liquid extraction processes such as furfural refining, propane deasphalting, and extraction and dephenolization of phenolic wastewater. Practice has shown that the high-efficiency extraction tower has the advantages of large processing capacity, low pressure drop, high mass transfer efficiency, and easy processing, manufacturing, and maintenance.

1) Filler characteristics:

1. By using FG type fillers to transform traditional rotary and packed extraction towers, the production capacity can be increased by more than 50%. When designing a new device, under the same processing capacity, the tower diameter can be reduced, equipment investment can be reduced, and the floor area can be reduced.

2. The porosity is large and can reach over 96%, with strong anti clogging performance.

3. The specific load of the tower is about 1.5 times that of traditional extraction towers.

4. High mass transfer efficiency ensures high extraction efficiency when the specific load of the tower is high.

5. Long service life, easy to maintain and reuse.

6. The smooth surface of FG type fillers can achieve enhanced clarification and separation, and reduce phase entrainment.

2) Filler classification:

Type I - light plate (used for coalescence settlement section);

Type II - circular pore (FG - Ⅱ - K) or tongue shaped pore (FG - Ⅱ - S) (used for mass transfer in extraction);

Type III - Support redistribution packing (used for support redistribution)

Industrial Application Performance of FG Honeycomb Tongue Grid Filler

|

Serial Number |

application device |

Tower diameter/m |

Production year |

Application unit |

Serial Number |

application device |

Tower diameter/m |

Production year |

Application unit |

|

|

1 |

Gasoline sweetening |

1.6 |

1992 |

Changling Refinery |

32 |

Refining of lubricating oil with furfural |

2.6 |

1996 |

Yumen Refining and Chemical Complex |

|

|

2 |

Gasoline sweetening |

1.2 |

1993 |

Changling Refinery |

33 |

Refining of lubricating oil with furfural |

1.8 |

1998 |

Karamay Refinery |

|

|

3 |

Gasoline sweetening |

1.6 |

1993 |

Wuhan Petrochemical Plant |

34 |

Refining of lubricating oil with furfural |

2.6 |

1999 |

Shenyang Paraffin Factory |

|

|

4 |

Liquid hydrocarbon sweetening |

1.4 |

1994 |

Anqing Petrochemical Plant |

35 |

Refining of lubricating oil with furfural |

2 |

2001 |

Lanzhou Refinery |

|

|

5 |

Gasoline sweetening |

1 |

1994 |

Anqing Petrochemical Plant |

36 |

Refining of lubricating oil with furfural |

3 |

2003 |

Yanshan Refining and Chemical Branch |

|

|

6 |

Liquid hydrocarbon sweetening |

1 |

1994 |

Jingmen Petrochemical Plant |

37 |

Propane deasphalting |

2.6 |

2001 |

Nanyang Oilfield Fine Paraffin Factory |

|

|

7 |

Gasoline sweetening |

1.8 |

1994 |

Jingmen Petrochemical Plant |

38 |

Propane deasphalting |

3 |

1993 |

Jinxi Refining and Chemical Complex |

|

|

8 |

Gasoline sweetening |

1.6 |

1994 |

Zhenhai Petrochemical Plant |

39 |

Propane deasphalting |

3 |

1997 |

Xinjiang Dushanzi Refinery |

|

|

9 |

Hydrogen sulfide removal from liquefied gas |

1.6 |

1994 |

Zhenhai Petrochemical Plant |

40 |

Propane deasphalting |

3.8 |

1997 |

Yumen Refining and Chemical Complex |

|

|

10 |

Hydrogen sulfide removal from liquefied gas |

1.6 |

1995 |

Zhenhai Petrochemical Plant |

41 |

Propane deasphalting |

2.8 |

1997 |

Maoming Petrochemical Company Refinery |

|

|

11 |

Hydrogen sulfide removal from liquefied gas |

1.6 |

1996 |

Harbin Refinery |

42 |

Propane deasphalting |

2.6 |

1999 |

Hohhot Refinery |

|

|

12 |

Liquefied gas sweetening |

1.4 |

1996 |

Harbin Refinery |

43 |

Propane deasphalting |

3 |

2000 |

Shanghai Gaoqiao Petrochemical Company Refinery |

|

|

13 |

Hydrogen sulfide removal from liquefied gas |

1.2 |

1997 |

Changling Refinery |

44 |

Propane deasphalting |

3 |

2002 |

Yanshan Refining and Chemical Branch |

|

|

28 |

Liquid hydrocarbon sweetening |

2.2 |

2005 |

Shijiazhuang Refinery |

45 |

solvent regeneration |

1.8 |

1995 |

Yanshan Refining and Chemical Branch |

|

|

29 |

Hydrogen sulfide removal from liquid hydrocarbons |

1.6 |

2006 |

Shenhua Coal to Liquid Co., Ltd |

46 |

Acrylonitrile quench tower |

2 |

2001 |

daqing petrochemical corp |

|

|

30 |

Refining of lubricating oil with furfural |

1.8 |

1993 |

Xinjiang Dushanzi Refinery |

47 |

Acrylonitrile quench tower |

2 |

2001 |

Anqing Petrochemical Company |

|

|

31 |

NMP refining of lubricating oil |

2.6 |

1996 |

Lanzhou Refining and Chemical Complex |

48 |

Hydrogen peroxide oxidation tower |

2 |

2004 |

SICHUAN CHEMICAL COMPANY LIMITED |

|

|

|

|

|

|

|

|

49 |

Wastewater phenol recovery extraction tower |

2.2 |

2008 |

Middling coal Longhua Company |

Related Products

Listening to each customer's heart

-

Follow us

Follow us

-

Scan mobile version

Scan mobile version

Copyright © 2023 Qidong Julong Petrochemical Equipment Co., Ltd. All Rights Reserved | Tags | Business License