JLM series metal microporous filter element fine filter

-

Pipeline reactor

-

Tower reactor

-

Tubular high efficiency heat exchanger

Product Introduction

The JLM series metal microporous filter cartridge fine filter is a new generation fine filter that our company has successfully launched in cooperation with domestic scientific research institutions, based on the introduction of advanced foreign technology. Its core component, the metal microporous filter element, has many excellent properties, such as large filtration area, high breathability, high pollutant holding capacity, high strength, high temperature resistance, corrosion resistance, high filtration accuracy, good purification efficiency, small pressure difference, cleanability and regeneration, convenient maintenance, and long service life. It has achieved the maximum process and economic benefits in the fields of fluid purification, impurity separation, and precious material recovery, and is widely used in industries such as petrochemical, fine chemical, chemical fiber, pharmaceutical, aviation, electronics, food, and beverage.

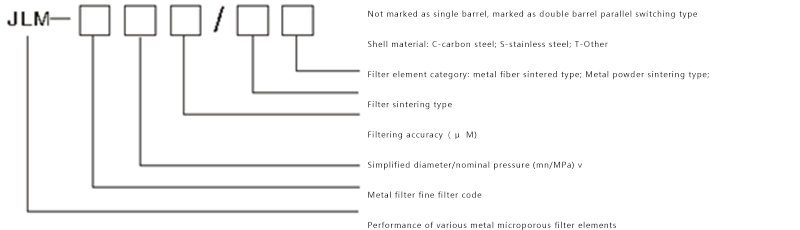

Product model representation method

(1) Stainless steel fiber sintered filter element

The stainless steel fiber sintered filter element produced by our company is made of porous deep type filter material made of stainless steel metal fiber (316L) after sintering and rolling, and then folded. Under the same external dimensions, the filtering area is 3-4 times that of conventional tubular filter elements. Therefore, it has a large processing capacity, low pressure drop, and the filter element can be cleaned and regenerated, with high filtration accuracy (0.3-60 μ m) It has the advantages of long service life and has the leading domestic level of the same product.

Note:

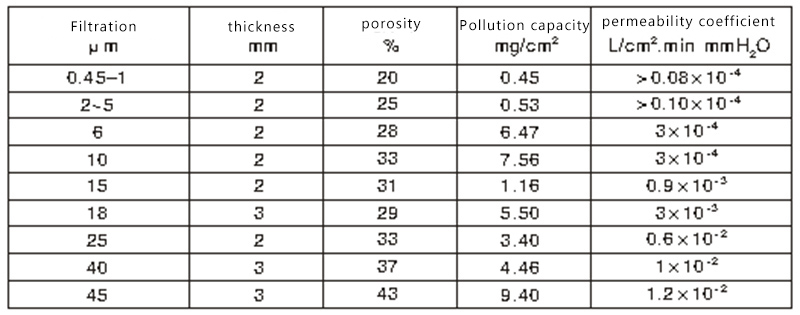

1. The pollution capacity test meets the 1SO4572 standard, and the final pressure drop of the filter material is 8 times the initial pressure drop.

2. The average permeability test meets the 1SO4022 standard, and the air pressure is 200Pa.

Typical application range of stainless steel fiber sintered filter element

Specification and dimensions of stainless steel fiber sintered filter elements

(2) Metal powder sintered filter element

The core of the metal powder sintered filter element is the powder metallurgy microporous sintered tube, which has the characteristics of high temperature resistance, corrosion resistance, uniform and stable pore size, good breathability, high mechanical strength, and can be cleaned and reused. The materials include bronze, stainless steel, titanium, nickel, etc. Widely used in industries such as petroleum, chemical, beverage, pharmaceutical, textile, metallurgy, hydraulic, pneumatic, etc. for solid-liquid and gas-solid separation, fluid and gas distribution, noise reduction, shock absorption, damping, liquid gasification, and flow limiting.

Main performance parameters of metal powder sintered filter materials

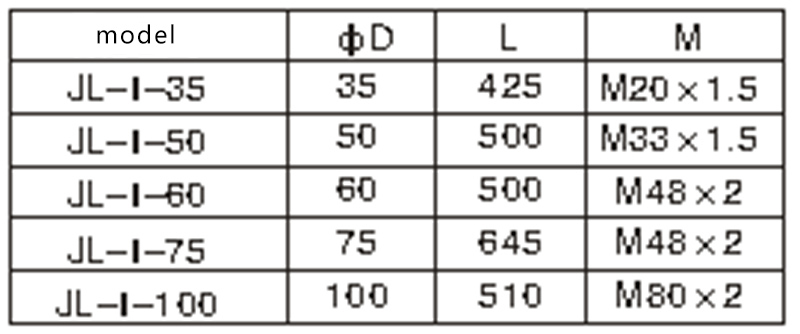

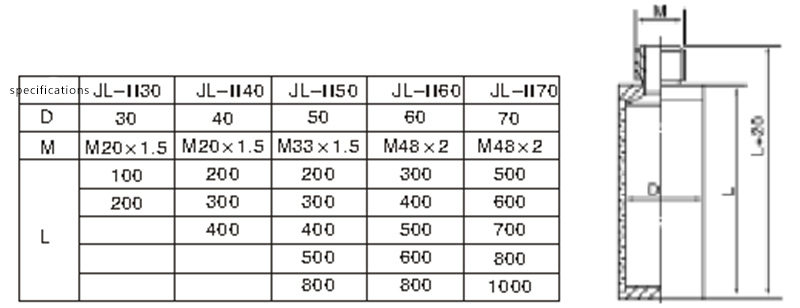

Specification and dimensions of metal powder sintered filter element

(3) Stainless steel filter sintered filter element

The filter element of the sintered stainless steel filter element is made of multi-layer stainless steel woven wire mesh through special processes such as lamination pressing and vacuum sintering. It is a new type of porous filter material with high strength and overall rigid structure. It overcomes the shortcomings of low strength, poor rigidity, and unstable mesh shape of ordinary woven metal wire mesh, and can reasonably match and design the pore size, permeability, and strength of the material, Thus, its comprehensive performance has been greatly improved, and its materials are 1Cr18Ni9Ti and 316L.

Main characteristics of sintered metal filter material

1. Stable mesh shape, uniform pore size, and no blind holes;

2. The aperture and strength can be reasonably configured through multi-layer mesh composite;

3. Good fluid permeability, high flow capacity, and low resistance loss;

4. High strength, high rigidity, and good assembly performance;

5. Wide material range, high temperature resistance, and good seismic resistance;

6. The pores are smooth and simple, easy to clean and regenerate, and have a long service life;

7. The filter has stable performance and is suitable for continuous and automated operation processes.

The metal filter sintered filter core fine filter is mainly suitable for the purification and filtration of gases or liquids, such as the purification of high-temperature gases, sewage filtration, filtration of various oil products, and filtration of chemical products such as paraffin and sulfur.

The main performance and specifications of sintered metal filter elements

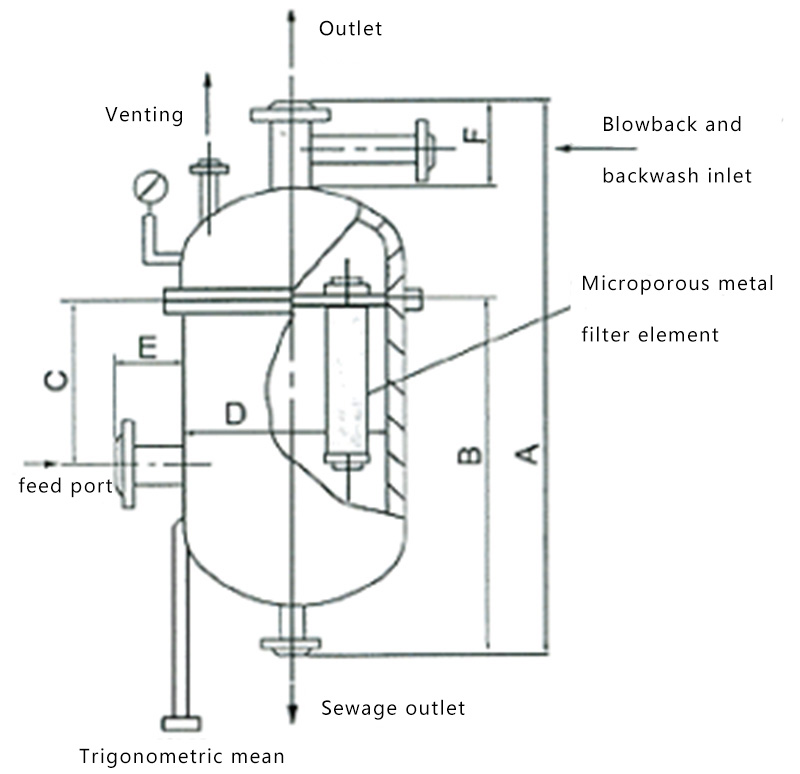

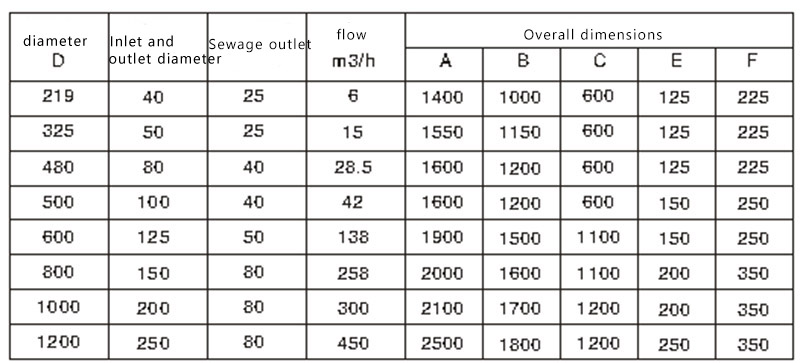

Structure diagram and technical parameters of metal microporous filter element fine filter

Structural diagram

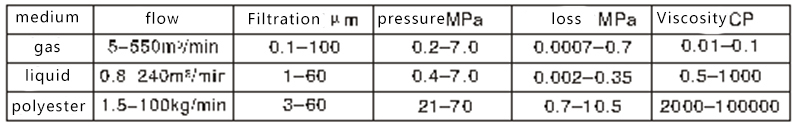

Technical Parameter

The data in the above table is for reference only

Special parallel switching design

In order to adapt to the process conditions that require continuous filtration, two filters are used in parallel. When one filter is shut down for backwashing, the other filter continues to operate, thus achieving the goal of long-term continuous operation of the system.

Related Products

Listening to each customer's heart

-

Follow us

Follow us

-

Scan mobile version

Scan mobile version

Copyright © 2023 Qidong Julong Petrochemical Equipment Co., Ltd. All Rights Reserved | Tags | Business License